The summary consists of:

- K00: Introduction to sustainable urban logistics

- K01: Vehicle, traffic and energy

- K02: Infrastructure and logistics process

- K03: Management, organization and communication

- K04: Business case

K00: Introduction to sustainable urban logistics

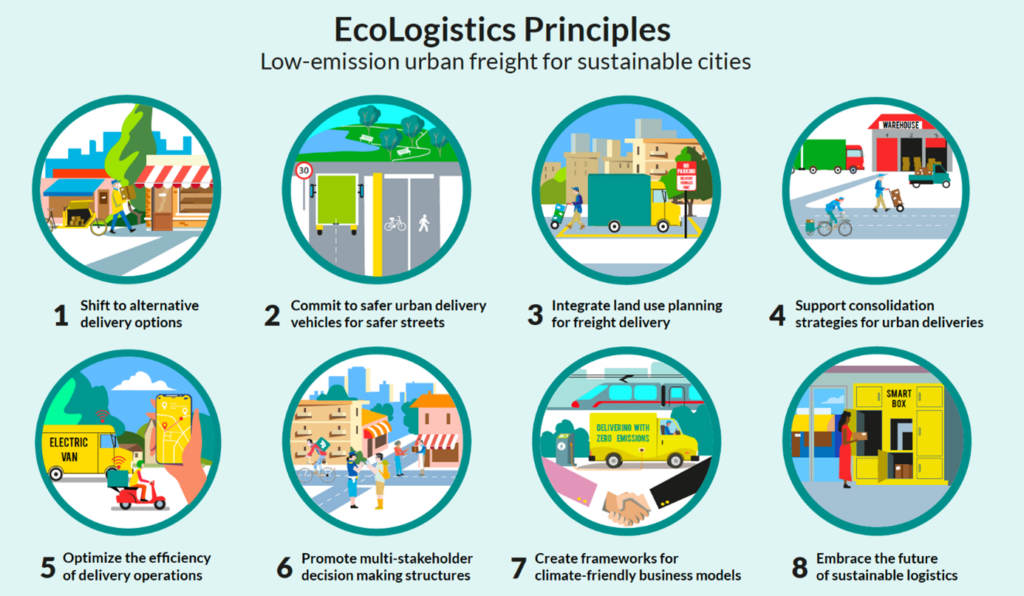

Sustainability and logistics is about finding new green solutions and a profitable business case. It is the integrated approach with thinking outside the box of the usual van and delivery truck. The major trend for urban logistics is the personalized on demand economy. Not only for consumers at home but also for the companies and shopping centers in the city. All these deliveries in a classical way will decrease the livability of the city centers. So to meet the climate goals and air quality goals in the city centers we should change to green logistics.

So this change should come and it is both an chance and a challenge. It is also a transition by technology, economy, policy from macro level towards the implementation on meso and micro level

The solutions should be integral (including vehicles, technology, energy, infrastructure, logistics, business case, management, et cetera) and adaptive to the transition moving in. It is action and experiment that drives this transition. So flexibility in the solutions is the key to sustainable solutions.

There is a chance to develop green growth on package services, meal delivery, renovation market and just-in-time delivery to retail and hospitality

The challenge is the change that comes in a planned time frame and the restrictions in which this should take place. In for example the Netherlands the green deal zero emission city logistics comes into full transition in more than 30 city centers in 2025.

The vocational course on sustainable city logistics covers four themes:

- Vehicle, traffic and energy

- Infrastructure and logistics process

- Management, organization and communication

- Business case

K01: Vehicle, traffic and energy

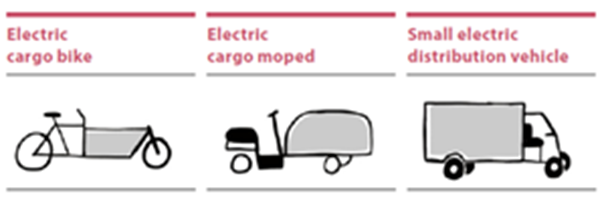

For vehicle, traffic and energy, solutions in letting the ‘goods’ move are chosen. So which vehicle, which technology and how to ensure safe traffic and availability of energy resources . Light electric freight vehicles (Figure) are here one of the solutions amongst others, for example battery or hydrogen electric trucks (Figure). The bottom line is the profitable business case with a minimal energy use per package delivered.

Here we distinguish: K01a) Vehicle choice, K01b)Traffic and transport safety and K01c) Energy supply

K01a: Vehicle choice

Logistical relocation can be realized with a wide range of vehicles: the modalities. In addition to the well-known trucks and vans, there are now also light trucks.

All vehicles will be electric or hydrogen electric to meet a sustainable city logistics goal,

As a result of this objective, more and more suitable vehicles are becoming available. Both from existing suppliers and from new producers. The proper and efficient use of the vehicles means a reduction in CO2 emissions over the entire chain

Due to the larger numbers, the cost price of the sustainable vehicles decreases and the associated charging and refuelling infrastructure is also realized.

In addition, the cities are taking policy measures to stimulate and ultimately make the use of sustainable vehicles mandatory. One of these measures is the window times regulation.

K01b: Traffic and transport safety

Traffic and transport safety in the logistics process are preconditions within which logistics must be realized. Road safety is about preventing accidents (active safety) and minimizing the consequences of accidents (passive safety).

In the context of this elective and the arrival of light electric freight vehicles, the question of safety in relation to other traffic arises. Light Electric Freight Vehicles are sometimes too big the bike lane and too small (and too slow) to mix so well with cars. In making city logistics more sustainable, the design of urban areas must therefore also be looked at carefully so that the right choices can also be made from that point of view.

Apart from that, the requirements with regard to the safe transport of the goods apply to all vehicles. Specific requirements are set for the food and therefore also for controlling the temperature of the goods.

K01c: Energy supply

In the coming years, the mobility sector will face a major challenge to further increase sustainability in which sustainable city logistics is very topical. In addition, sustainability is taking place in all other sectors.

In order to be able to reduce, we have to use the energy in a smart way. So we also start by reducing energy consumption by using the right vehicle in the right way. So making good use of the loading capacity and, where possible, transporting the largest flows with the largest vehicles. It concerns the combination of LEVVs, vans and trucks.

It is important to calculate back to consumption per kg per km and then it appears that the difference in the modalities is strongly determined by how they are used. That’s worth a calculation.

This also applies to the use of hydrogen, which is less energetically beneficial in terms of the usability (range) of the vehicles than battery electric vehicles.

Finally the green (!) energy must also come from somewhere: so is there sufficient charging and / or refueling capacity and where is it located? And it will remain sufficiently available if there is an increasing demand for green energy?

K02: Infrastructure and logistics process

Infrastructure and logistic process describes the logistic chain on last mile delivery. As mentioned before this covers only a part of the city logistics. So also here we have to combine the classical and new logistic chains. Furthermore this should be integrated in the infrastructure of the city: so where should we locate a hub and for example park and maintain the cargo bikes

The short definition of logistics is: “Deliver the right items, at the right time, in the right place, in the right quantity at minimum cost to the recipient”. City logistics is the part of the logistics chain in which the ‘last mile’ delivery is provided. There are a number of important differences between logistics and city logistics that you need to take into account:

- Logistics looks at the big picture, so everything that is transported from A to B and especially in large quantities, with large vehicles, preferably Longer and Heavier Truck Combinations (LHVs)/Ecocombi’s (ECs) or Super Ecocombi’s (SEC’s).

- In city logistics, we look at the picture in and around the city. City logistics is part of the entire logistics chain, but focuses specifically on the ‘last mile’.

- City logistics uses sustainable, energy-efficient vehicles, such as Light Electric Freigh Vehicles or Zero emission small trucks.

- In order to obtain a better filling rate of the vehicles, cooperation between different carriers is important to make sustainable city logistics cost-efficient. This can be done, for example, by using a joint hub.

Infrastructureis the set of facilities necessary for a country or organisation, such as a company or an institution, to function properly. The traffic infrastructure includes facilities for traffic and transport, such as the road network, railways, airports, waterways and ports, cabling, sewerage, cable connections for telephone traffic and data communication and the drinking water supply network. Because it is getting busier in cities and there are more regulations in the field of the environment, the infrastructure is constantly changing.

For sustainable city logistics, it is important to have knowledge of the infrastructure of a city. This makes it easier to plan the fastest routes and to be able to respond quickly to unexpected situations. This results in time savings, satisfied customers and ultimately profit.

K03: Management, organization and communication

A different way of working will request also a different way of organizing the work, the management of the flexible use of modalities and communication in the logistic process (like traceability of the packages).

Here we distinguish: K03a) Management, K03b)Distribution network, K03c) Cost, K03d) Planning and control, K03e) Human factor and K03f) Business model canvas

K03a: Management

Management is leading a company, the employees within that company and communicating with your stakeholders. This means that as a manager you constantly have to make difficult choices about the way you organize the company and the way you communicate. The choices you make determine whether you make a profit and how much profit you make.

Managers of logistics companies have had to deal with challenges in sustainable logistics. For example, all kinds of requirements from the government (and from customers / consumers) to reduce the emission of CO2, particulate matter and NOx have been added. This requires new choices with regard to the use of means of transport, cooperation with other companies and municipalities and the deployment and management of personnel. When making these choices, attention will have to be paid to the costs to ensure that a profit is made. A good consideration of advantages and disadvantages with regard to the many options and smart solutions are necessary.

K03b. Distribution network

There are many factors that determine whether deploying Light Electric Freight Vehicles is a good idea. In general, Light Electric Freight Vehicles are suitable for shorter, time-critical journeys in busy, urban areas. Light Electric Freight Vehicles are often faster there than vans. Light Electric Freight Vehicles are also suitable for the transport of goods with a limited weight and volume.

The location of the hub has a major influence on the successful deployment of Light Electric Freight Vehicles. Hubs on the outskirts of the city or in the city ensure that Light Electric Freight Vehicles can make short trips and are therefore regularly a better option than vans.

Companies can choose to organize or outsource the logistics themselves. Most companies outsource at least part of it to a logistics service provider. The main reasons for this are: Concentration on the core activity, no worries about (extra) personnel, financial benefit and better insight into the logistics costs.

K03c: Cost

In logistics, it is important to organize the flow of goods as efficiently as possible in order to keep costs as low as possible. With the arrival of the Light Electric Freight Vehicles, an extra option has been added to transport goods.

There are several costs that you have to take into account when deploying Light Electric Freight Vehicles, namely the cost of the vehicles (TCO, Total Cost of Ownership), the wage costs, the route costs, the costs for loading and unloading and the costs of the hub.

If you have insight into the costs of deploying Light Electric Freight Vehicles, you can organize goods flows more efficiently by splitting them into different modalities based on the cost information. This way you can make a decision about whether or not to use Light Electric Freight Vehicles for a company.

The costs consist of the costs for purchasing and using the vehicles, the labour costs, the route costs, the costs for loading and unloading and the costs of the hub.

Because the use of Light Electric Freight Vehicles is not always financially attractive for companies, the government plays an important role. The government can stimulate the use of hubs and mutual cooperation between companies. For example, by providing a (temporary) subsidy.

K03d: Planning and control

Switching to working with Light Electric Freight Vehicles in the city centre requires adjustments to the distribution network and making good economic decisions. Working with Light Electric Freight Vehicles also requires a different way of making schedules. In addition, adjustments are also needed in the transport management systems.

When making a trip and route planning for working with Light Electric Freight Vehicles, several factors must be taken into account. For example, the fastest route must be calculated, whereby obstruction for vans (window times, one-way roads, cycle paths) should not be included because these often do not apply to Light Electric Freight Vehicles. We must also take full advantage of working with Light Electric Freight Vehicles by planning many short trips with many stops. Finally, the battery life of the battery and a different maximum speed must be taken into account.

For planners of transhipment processes, working with Light Electric Freight Vehicles often means an extra link in the logistics process. They must take into account different vehicles that have different characteristics, such as capacity, speed and range. In addition to adjusting the planning, an extra link in the logistics chain often also means extra administrative and financial processes.

Finally, working with Light Electric Freight Vehicles presents a challenge for transport management systems. These systems must be able to calculate the fastest route for Light Electric Freight Vehicles in the inner city. In addition, real-time data, such as the status of the battery, must be easy to read. The new system must also fit in well with existing systems to keep an eye on the total route of a product or service.

K03e: Human factor

Working with Light Electric Freight Vehicles means change for drivers who were used to driving traditional vans. For example, driving other routes, less comfort in the vehicle and more working in the open air.

For planners and employees in the back office, working with Light Electric Freight Vehicles can also cause changing activities. For example, monitoring real-time data and responding quickly to unexpected situations.

Meanwhile, research is also being done into autonomous Light Electric Freight Vehicles. Although autonomous LEVVs bring benefits, they are not yet widely deployed. Often the use of autonomous Light Electric Freight Vehicles is not yet profitable.

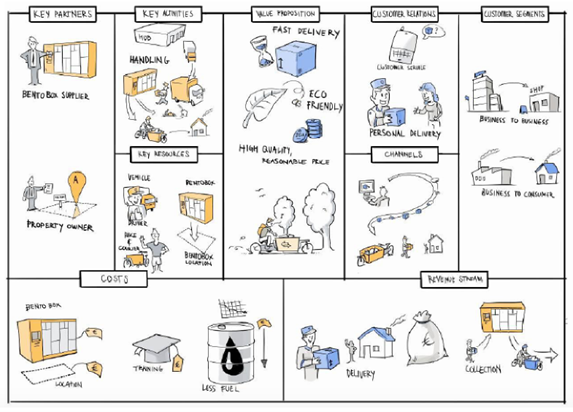

K03f: Business model canvas

One of the problems with the introduction of new concepts for city logistics is the lack of a revenue model; no money is earned. The Business Model Canvas is a tool to provide insight into how, taking into account all kinds of factors and preconditions, profit can still be made. Completing the checklist can help managers make the right choices.

K04: Business case

The business case brings all together. How to make a start with the sustainable business case, initially subsidized, but finally to find solutions which are profitable by itself. Here learning by doing is part of the innovation process.

You determine what is needed to achieve an emission-free ‘last mile’ supply (incl. return flows) of a specific logistics flow (e.g. facility logistics, construction logistics, waste logistics, supermarket logistics, food logistics, parcel services, etc.).

You have to take into account the organization, infrastructure and mode of transport of the logistics processes involved.

With this Business Case you have to take into account that the right mix of living, recreation and working (which ensure a vibrant and liveable city center) should not be lost sight of. Both the design and management and the management of the processes in sustainable city logistics must be addressed.

Factors to be identified/investigated are:

- Loading/unloading times;

- Nuisance;

- City hub / Streethub;

- Local infrastructure;

- Location;

- Consequences of nuisance etc;

- Bundling flows;

- All logistics flows (facility logistics, construction logistics, waste logistics, supermarket logistics, food logistics, parcel services etc)